Our Commitment

Since 2020, Unifold has proudly worked with Sydney's UTS Tech Lab, utilising their cutting-edge facilities and expert-led testing services to advance product innovation and deliver exceptional performance outcomes.

At UTS Tech Lab, our products undergo a comprehensive suite of standards and compliance testing, ensuring they meet both Australian and international regulations.

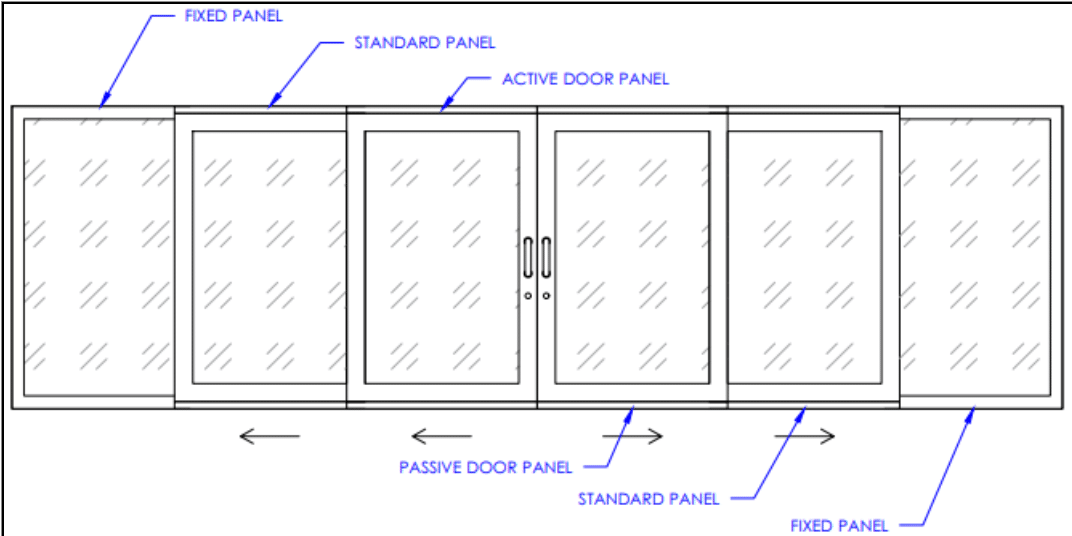

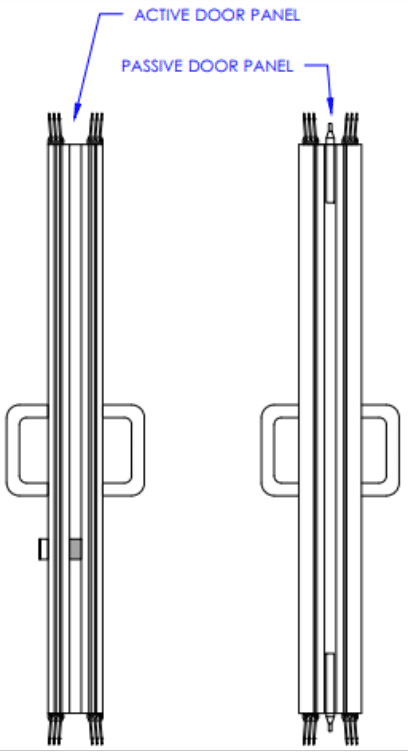

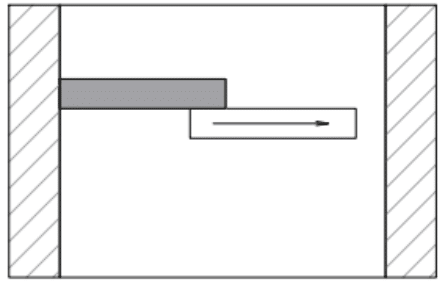

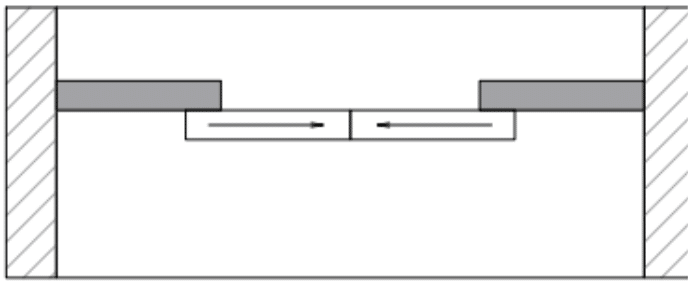

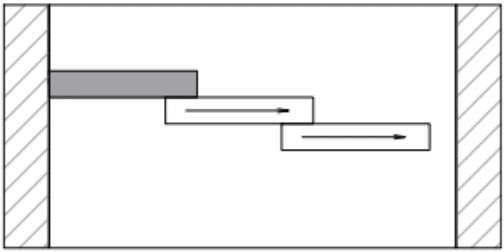

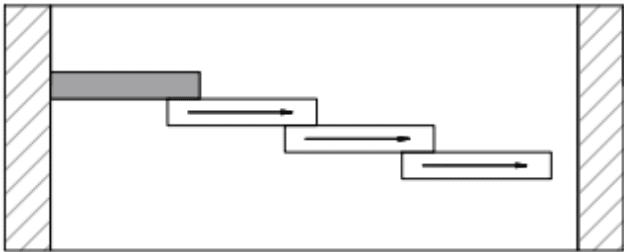

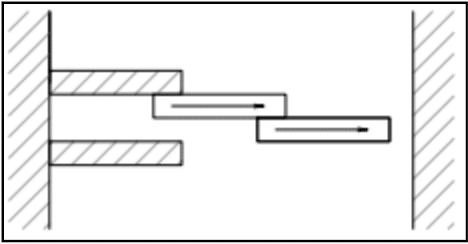

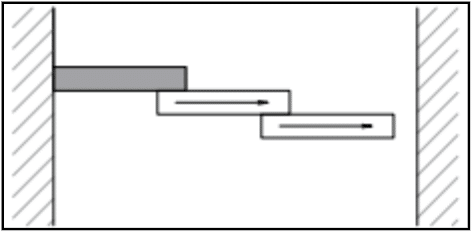

Comprehensive Product Range

Our range spans from versatile mid-level acoustic solutions through to industry-leading Rw performance, giving you the flexibility to balance cost, practicality, and premium sound insulation — without ever compromising on quality.

Expert-Led Testing

Utilizing cutting-edge facilities at UTS Tech Lab

Comprehensive Compliance

Meeting both Australian and international regulations

Flexible Solutions

From mid-level to premium acoustic performance